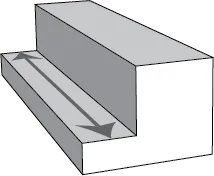

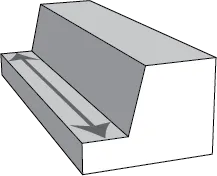

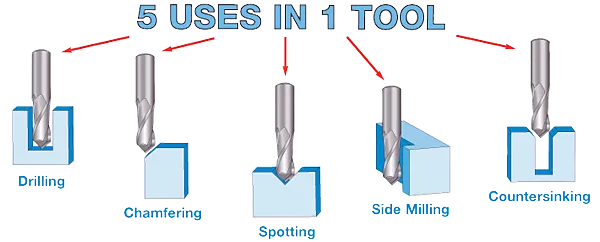

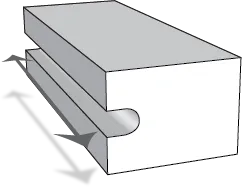

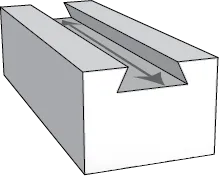

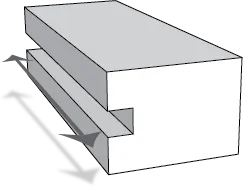

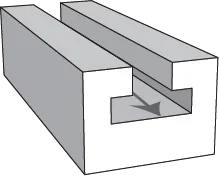

End Mills are solid shank milling tools designed to use side cutting flute edges to machine most materials. There are two cutting styles. Non-center cutting (side cutting only) and center cutting (side and end plunge cutting). End mills listed here are to be considered center cutting except where non-center cutting is indicated.

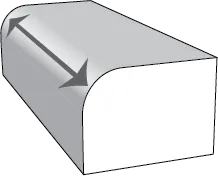

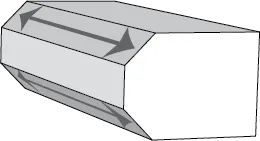

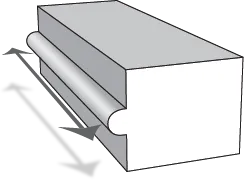

The ends come in many shapes depending on the type of plunge/center cut or side/contouring cut needed. Available with two flutes, three flutes, four flutes, six flutes and even eight flutes for cutting. More flutes reduces chip load and can improve the surface finish. End mills may have cutting surfaces on one (single end) or both ends (double end). There are a variety of flute lengths and overall lengths including stub length, regular length, long flute, long length, extra long flute, and extended length.

Looking only for Solid Carbide End Mills? Click Here

Single End - 2 Flute - HSS - METRIC page 257

Double End - 2 Flute - HSS page 255

Double End - 2 Flute - HSS - METRIC page 257

Single End - 2 Flute - HSS - Aluminum Cutting page 262

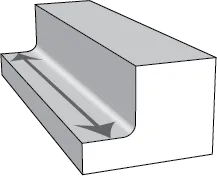

Single End - 2 Flute - HSS - Keyway Tolerance page 254

Single End - 2 Flute - HSS - Long Flute page 255

Single End - 2 Flute - HSS - Extra Flute page 255

Single End - 2 Flute - HSS - Extra Length page 255

Single End - 3 Flute - HSS - Aluminum Cutting page 262B

Single End - 3 Flute - HSS - Long Flute - Aluminum Cutting page 262B

Single End - 4 Flute - HSS page 260

Single End - 4 Flute - HSS - Metric (non-center cuting) page 263

Single End - 4 Flute - HSS - Metric page 263A

Double End - 4 Flute - HSS (non-center cuting) page 261

Double End - 4 Flute - HSS page 261

Double End - 4 Flute - HSS - Metric (non-center cuting) page 263

Double End - 4 Flute - HSS - Metric page 263A

Single End - 4 Flute - HSS - Long Flute page 260

Single End - 4 Flute - HSS - Extra Long Flute page 260

Single End - 8 Flute - HSS (non-center cuting) page 258

Single End - 2 Flute - Solid Carbide - Metric page 274

Double End - 2 Flute - Solid Carbide page 270

Single End - 2 Flute - Solid Carbide - Long Length page 271

Double End - 4 Flute - Solid Carbide - Stub Length - Metric page 274

Double End - 4 Flute - Solid Carbide page 272

Double End - 2 Flute - Super Cobalt page 266

Double End - 4 Flute - Super Cobalt page 267

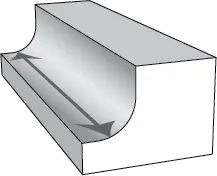

Double Ball End - 2 Flute - HSS page 256

Single Ball End - 2 Flute - HSS - Aluminum Cutting page 262A

Single Ball End - 2 Flute - HSS - Long Length - Aluminum Cutting page 262A

Single Ball End - 2 Flute - HSS - Extra Length page 256

Double Ball End - 2 Flute - Solid Carbide - Stub Length - Metric page 274

Single Ball End - 2 Flute - Solid Carbide - Metric page 270

Double Ball End - 2 Flute - Solid Carbide page 270

Single Ball End - 3 Tapered Flutes - Solid Carbide (non-center cutting) page 277

Double Ball End - 4 Flute - Solid Carbide - Stub Length - Metric page 275

Single Ball End - 4 Flute - Solid Carbide - Metric page 272

Double Ball End - 4 Flute - Solid Carbide page 272

Single Ball End - 3 Tapered Flutes - Solid Carbide (non-center cutting) page 277

Solid Carbide Roughing End Mills - Type "N" page 269

Solid Carbide Roughing End Mills - Type "S" page 269

Woodruff Key Seat (Shank) Cutters - Staggered Teeth page 282

Cobalt Roughing T-Slot Cutters page 281